Water cooling plastic pelletizing recycling machine

Inquiry Basket

Product Details

Water cooling plastic pelletizing recycling machine

The Water cooling plastic pelletizing recycling machine is designed for the recycling of plastic products such as HDPE, LDPE, and PP. This plastic recycling machine features inverter-controlled speed, which conserves energy. Additionally, the granulating crusher is equipped with an adjustable speed motor, ensuring ease of operation and high capacity.

Features of the Water Cooling Plastic Pelletizing Recycling Machine:

Compatible with LDPE, HDPE, LLDPE, and PP materials.

Designed for various material forms, including film, bags, and flakes.

Inverter control for extruder speed enhances energy efficiency, promoting eco-friendliness and cost savings.

Includes extruder, pelletizing unit, and water cooling unit.

One-year warranty; the machine operates continuously, 24/7.

User-friendly design ensures ease of operation.

Economically designed, making it ideal for beginners and startups.

Available in power options of 220V, 380V, 440V, and 480V (customized per request, e.g., USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz).

Comprehensive after-sales support, including engineer visits for installation and training services.

We welcome customer requests for customized machines or OEM designs.

plastic recycling machine

Service System(Plastic Granulating Machine):

· Pre-sale: we given client the details technician offer, sign the sales contract etc.

· In-sales: we supply the details layout, installation instruction, technician support for the clients;

· After sales: we arrange engineer to install the machinery and training the workers for client;

· We have 24hours team to solve the after sales problem;

· We have free spare parts with the machine;

– We always up date the new technology to every customer

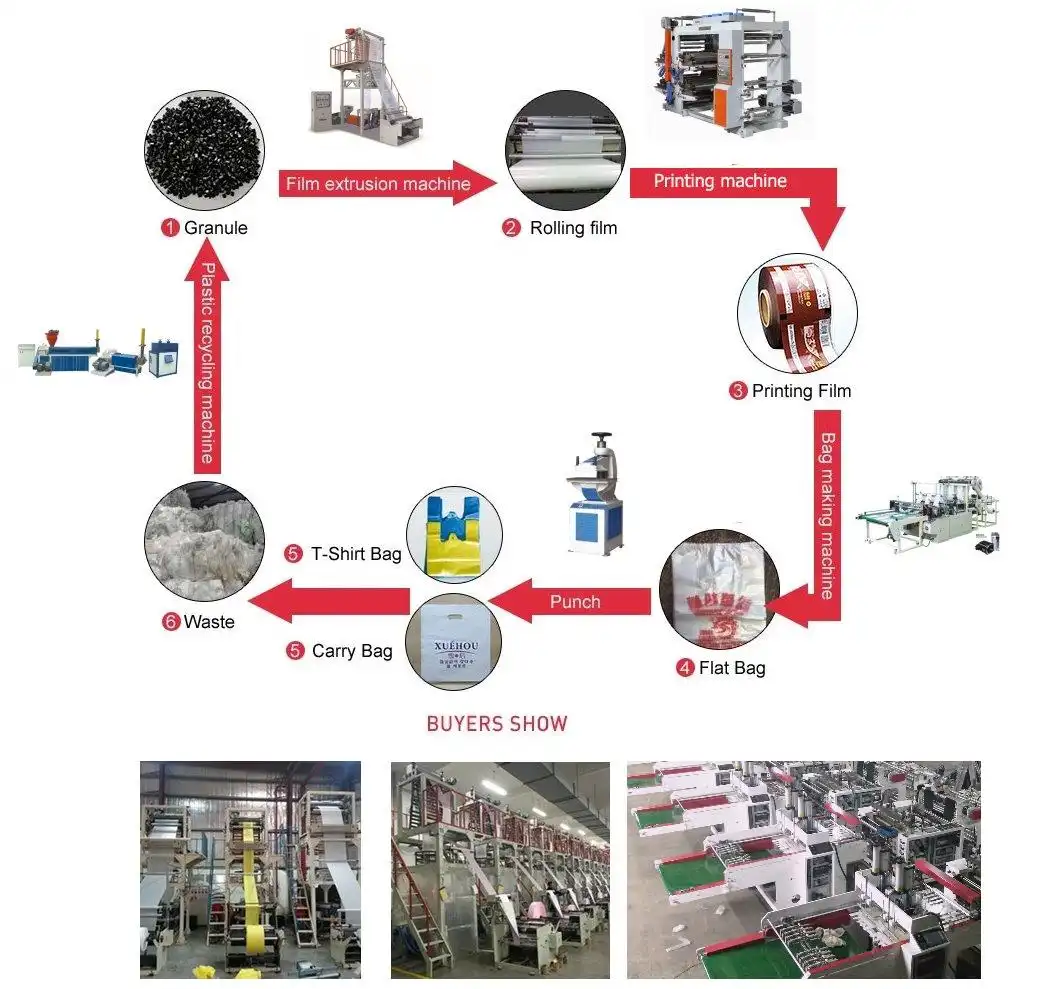

Plastic recycling is the process of recovering scrap or waste plastic and reprocessing the material into useful products. Since the vast majority of plastic is non-biodegradable, recycling is a part of global efforts to reduce plastic in the waste stream, especially the approximately 8 million tons of waste plastic that enters the Earth’s ocean every year.

Main Technical Variables:

| Model | SJ-90 | SJ-100 | SJ-110 | SJ-120 |

| Type Diameter of Screw Stem | φ90 | φ100 | φ110 | φ120 |

| Major Diameter Ratio of Screw Stem | L/D 20:1 -22:1 | L/D 20:1 -22:1 | L/D 20:1 -22:1 | L/D 20:1 -22:1 |

| Rational Speed of Screw Stem | 10-100r/min | 10-100r/min | 10-100r/min | 10-100r/min |

| Main Motor Power | 22kw | 30kw | 37kw | 45kw |

| Output | 68kg/h | 95kg/h | 120kg/h | 135kg/h |

| Weight of overall(kg) | 2600kg | 2800kg | 3000kg | 3200kg |

| Cover dimensions (l×w×h) (mm) | 4000×1500×1800 | 4000×1500×1800 | 4000×1500×1800 | 4000×1500×1800 |

| Power Voltage | 220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz…) | |||

| Machine Working Time | 24 hours * 7 days | |||

| Warranty | 1 year | |||

| Technical Assistance | Engineers available to service machinery overseas | |||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

plastic recycling machine

plastic crusher PE PP PET PVC

Shipment

shipment of plastic bag machine

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

instalment service

install machines in customer factory

Machine parts supplier

Our Main parts cooperator as following brand,but standard parts all made from China.

Material supplier

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company